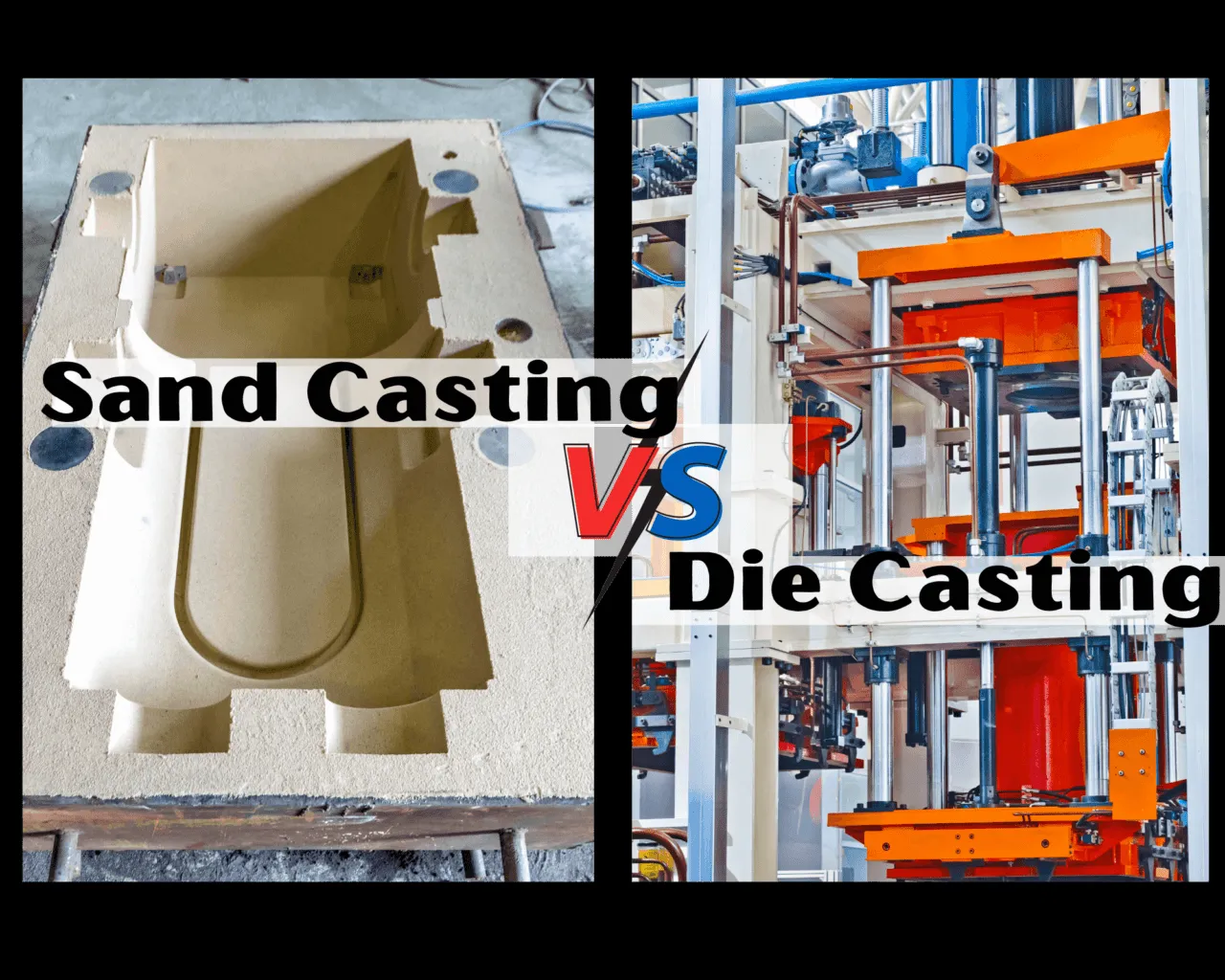

Diecast vs Sand Cast Choosing the Right Method

Choosing between diecast and sand cast methods is a crucial decision in the manufacturing process, impacting product quality, cost, and production efficiency. Both techniques offer unique advantages and disadvantages, making the selection process dependent on specific project requirements. This comprehensive guide examines the intricacies of each method, comparing their processes, benefits, and limitations to empower you to make an informed decision and find the optimal casting solution for your needs. Understanding these fundamental differences will help you navigate the complexities of metal casting and select the best approach.

Understanding Diecast Casting

Diecast casting is a high-volume manufacturing process where molten metal is forced into a mold cavity under high pressure. This method is known for its ability to produce complex shapes with high precision and excellent surface finish. The process typically utilizes reusable steel molds, called dies, which are designed to withstand the extreme temperatures and pressures involved. Diecasting is particularly well-suited for producing parts with intricate details, thin walls, and tight tolerances. The process is also relatively fast, allowing for high production rates, which makes it suitable for mass production in various industries.

The Diecasting Process Explained

The diecasting process involves several key steps. First, the die is created, usually from hardened tool steel, and is designed to the specific shape of the desired part. The die is then clamped shut and molten metal, typically aluminum, zinc, or magnesium alloys, is injected into the die cavity under high pressure. The metal solidifies rapidly, taking the shape of the mold. After the metal has solidified, the die is opened, and the casting is ejected. The part may then undergo trimming, finishing, and machining to achieve the final product. The speed and efficiency of the diecasting process allow for rapid production cycles and high output volumes.

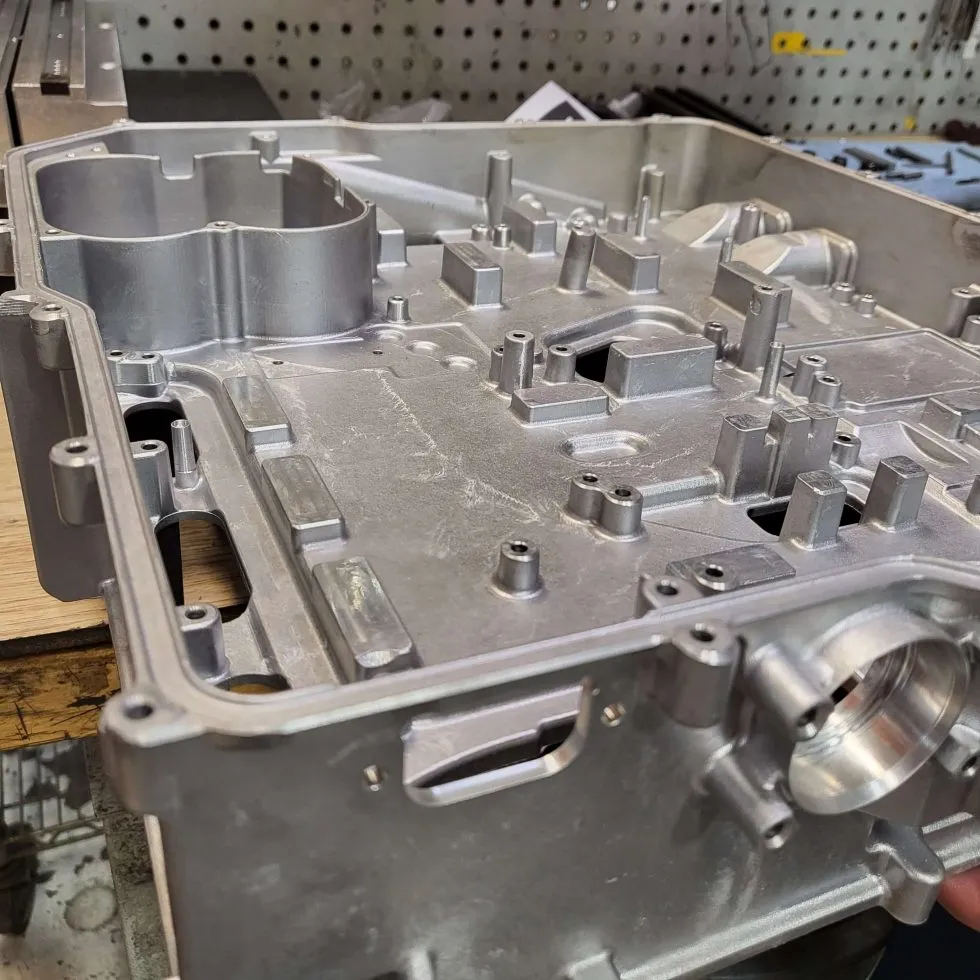

Advantages of Diecast Casting

Diecast casting offers numerous advantages, including the ability to produce parts with complex geometries and intricate details. The high precision of diecasting results in tight tolerances and excellent dimensional accuracy, minimizing the need for secondary machining operations. The process also provides a superior surface finish, reducing or eliminating the need for post-casting surface treatments. Moreover, diecasting is highly efficient and allows for rapid production cycles, making it ideal for high-volume manufacturing. Diecast components also exhibit good mechanical properties, making them suitable for various applications in industries such as automotive, electronics, and consumer products.

Precision and Accuracy in Diecast

One of the greatest strengths of diecasting is the ability to achieve high precision and accuracy. This method allows for the creation of parts with tight tolerances, often within a few thousandths of an inch. This precision is critical for applications where dimensional accuracy is paramount. The high pressure used in the process ensures that the molten metal fills every detail of the mold, resulting in complex designs. The precision and accuracy offered by diecasting significantly reduce the need for secondary machining, saving time and reducing manufacturing costs.

Material Selection for Diecast Casting

A wide range of materials can be used in diecasting. Common choices include aluminum alloys, which offer a good balance of strength, weight, and corrosion resistance. Zinc alloys are another popular option, known for their excellent castability and ability to produce intricate details. Magnesium alloys are favored for their lightweight properties and high strength-to-weight ratio. These materials are chosen based on the required performance characteristics of the final product, including mechanical strength, thermal properties, and corrosion resistance. The selection of the right material is critical for the success of the diecasting process.

Disadvantages of Diecast Casting

While diecasting offers many advantages, it also has some limitations. The initial cost of creating the dies can be high, making diecasting less economical for short production runs. The process is also limited to materials that can withstand the high temperatures and pressures involved. Diecast components may also have some porosity, which can affect their mechanical properties. Furthermore, the complexity of die design and manufacturing can be time-consuming. Despite these disadvantages, diecasting remains a highly efficient and versatile manufacturing process for a wide range of applications.

Sand Cast Explained

Sand casting is a casting process that uses sand as the primary mold material. It is one of the oldest and most versatile methods of metal casting. In this process, a mold is created by packing sand around a pattern, which is a replica of the part to be produced. Once the mold is formed, the pattern is removed, leaving a cavity. Molten metal is then poured into the cavity, and allowed to cool and solidify, after which the sand mold is broken and the casting is extracted. Sand casting is well-suited for producing large parts, complex geometries, and parts made from a wide range of metals.

The Sand Casting Process

The sand casting process begins with the creation of a pattern, which is often made of wood, metal, or plastic. The pattern is placed in a flask, a frame that holds the sand, and sand is packed around the pattern. The sand is typically mixed with a binder to hold the mold together. After the mold is formed, the pattern is removed, leaving a cavity in the shape of the desired part. Molten metal is then poured into the cavity through a system of channels called gates and runners. After the metal solidifies, the sand mold is broken, and the casting is removed. The casting is then cleaned, and may undergo finishing operations.

Advantages of Sand Casting

Sand casting offers significant advantages, including the ability to produce large and complex parts with relatively low tooling costs. The process is flexible and can accommodate a wide variety of metal alloys, including steel, iron, aluminum, and copper alloys. The cost of setting up a sand casting operation is generally lower than that of diecasting, making it suitable for short production runs and prototypes. Sand casting also allows for the production of intricate internal features and undercuts. The process is ideal for parts with simple or complex geometries where high precision is not a primary requirement.

Cost-Effectiveness of Sand Casting

One of the major benefits of sand casting is its cost-effectiveness, particularly for low to medium production volumes. The tooling costs associated with sand casting are typically lower than those for diecasting, primarily due to the use of sand molds, which are less expensive to manufacture. This makes sand casting an attractive option for projects with budget constraints or those requiring a smaller number of parts. The reduced tooling costs make sand casting an economically viable choice for prototypes, custom parts, and products with limited production runs.

Material Options for Sand Casting

Sand casting offers a broad selection of materials. It can be used with virtually any castable metal alloy, including various types of steel, iron, aluminum, copper, and bronze. The selection of the right material is based on the intended use and requirements of the part. The ability to cast a diverse range of metals makes sand casting incredibly versatile and adaptable to a multitude of applications, making it a preferred choice for a wide array of industries.

Disadvantages of Sand Casting

Sand casting has certain limitations. The surface finish and dimensional accuracy are typically not as high as those achieved with diecasting. The process is slower than diecasting and is generally not suitable for high-volume production runs. The surface finish of sand castings can be rough, often requiring extensive finishing operations. Moreover, the mechanical properties of sand-cast parts may not be as uniform as those of die-cast parts. Despite these limitations, sand casting remains a valuable technique for producing large and complex parts at a reasonable cost.

Diecast vs Sand Cast A Comparison

When comparing diecast and sand cast, several factors must be considered to determine the best choice for a specific project. Each process excels in different areas, and the optimal selection depends on the production volume, complexity of design, required surface finish, and material properties. Making the correct choice at the outset of the project can lead to the best balance of performance, cost, and quality for the manufactured parts.

Cost Analysis

Cost is a critical factor in choosing between diecast and sand cast. Diecasting has high initial tooling costs, making it more economical for high-volume production runs. Sand casting has lower tooling costs, making it more suitable for short production runs and prototypes. While the cost per part is typically lower for diecast in large volumes, the initial investment can be prohibitive for smaller projects. Considering the total cost, including tooling, material, labor, and finishing, is vital for making an informed decision.

Production Volume

Production volume significantly influences the choice between diecast and sand cast. Diecasting is ideal for high-volume manufacturing due to its rapid production cycles. Sand casting is more appropriate for low to medium production volumes or projects that require a relatively small number of parts. The faster production rates of diecasting lead to lower per-unit costs in high-volume scenarios. Understanding the expected production volume is therefore essential when evaluating the best casting method to use.

Complexity of Design

The complexity of the part design is another important consideration. Diecasting is well-suited for producing complex geometries and intricate details with high precision. Sand casting can also handle complex designs, but with potentially lower precision and surface finish. For parts with intricate features, thin walls, and tight tolerances, diecasting is often the preferred option. For parts with simpler designs where precision is less critical, sand casting can be a more cost-effective solution.

Surface Finish and Tolerances

Surface finish and dimensional tolerances are critical factors, with diecasting generally offering superior results. Diecast parts have a smoother surface finish, reducing or eliminating the need for post-casting surface treatments. The tight tolerances achieved with diecasting minimize the need for secondary machining operations, improving efficiency and reducing costs. Sand-cast parts typically have a rougher surface finish and looser tolerances, often requiring additional finishing processes. If a high-quality surface finish and tight tolerances are essential, diecasting is the superior choice.

Material Properties

The mechanical properties of the materials used also influence the choice. Diecasting is often preferred for parts requiring high strength and good mechanical properties. Sand casting offers a wide range of material options and is suitable for parts that don’t require the same level of mechanical performance. When evaluating material properties, consider strength, ductility, corrosion resistance, and thermal properties. The selection of the right material and casting method is crucial for achieving the desired performance characteristics of the finished product.

Choosing the Right Casting Method

Selecting the optimal casting method between diecast and sand cast requires careful consideration of all relevant factors. By evaluating the production volume, design complexity, surface finish requirements, material properties, and cost implications, you can make an informed decision. Consider the long-term needs of your project and weigh the advantages and disadvantages of each method. Understanding the strengths of each casting process will help you choose the best solution, leading to a successful manufacturing outcome, and delivering high-quality, cost-effective parts.