Understanding Diecast Mold Design

Diecast mold design is a critical aspect of the manufacturing process, specifically within the realm of die casting. It encompasses the intricate art and science of creating molds that can withstand high pressures and temperatures to produce precise and complex metal parts. The effectiveness of a diecast mold design directly influences the quality, efficiency, and cost-effectiveness of the final product. A well-designed mold ensures that molten metal flows smoothly, solidifies correctly, and is easily ejected, leading to parts with superior dimensional accuracy and surface finish. This article delves into the secrets behind effective diecast mold design, exploring its essential elements, advanced techniques, and best practices to help manufacturers optimize their processes.

What is Die Casting

Die casting is a metal casting process characterized by forcing molten metal under high pressure into a mold cavity. The mold, known as a die, is created from two halves and is typically made from steel alloys for durability. Once the molten metal solidifies, the die opens, and the finished part is ejected. This method is ideal for producing a large volume of parts with high precision, making it a cornerstone process in various industries. Die casting allows for intricate geometries and fine details that are often unattainable with other casting methods. The process provides a high degree of automation, leading to reduced labor costs and faster production cycles. Different metals, including aluminum, zinc, magnesium, and copper alloys, can be die cast to meet specific performance requirements.

The Die Casting Process

The die casting process involves several key steps, starting with mold preparation and clamping. The die halves are securely closed and locked. Molten metal is then injected into the die cavity under high pressure. This pressure ensures that the metal fills the cavity completely, reproducing the shape of the part with high accuracy. After the metal solidifies within the die, the mold opens, and the part is ejected using ejector pins. The part then undergoes trimming to remove excess material, such as gates and runners. Subsequent operations might include surface finishing, heat treatment, and machining, depending on the part’s specifications and desired properties. The precise control over these stages and the materials used determines the final quality and characteristics of the cast component. (die-casting-process.webp)

Benefits of Die Casting

Die casting provides numerous benefits, including the ability to produce complex geometries with excellent dimensional accuracy and surface finishes. The process is suitable for high-volume production runs, making it cost-effective for manufacturers. Die-cast parts can be manufactured with thin walls, reducing material usage and weight. The rapid cooling inherent in the die casting process contributes to fine grain structures, improving the mechanical properties of the parts. Die casting offers a wide range of material options, including aluminum, zinc, and magnesium, allowing engineers to select the best material based on performance, weight, and cost requirements. The process also facilitates various secondary operations, such as machining, plating, and painting, expanding the design possibilities.

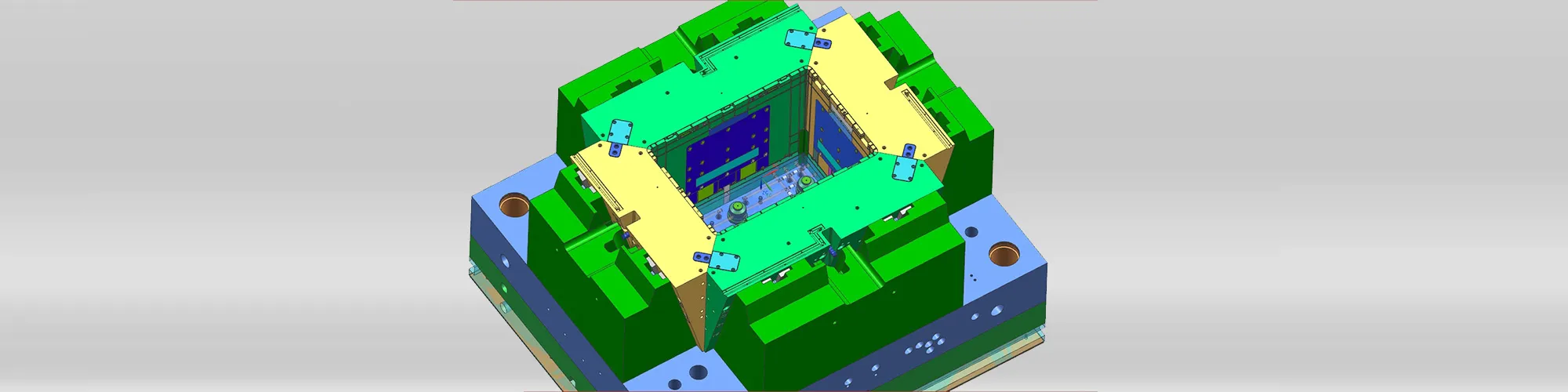

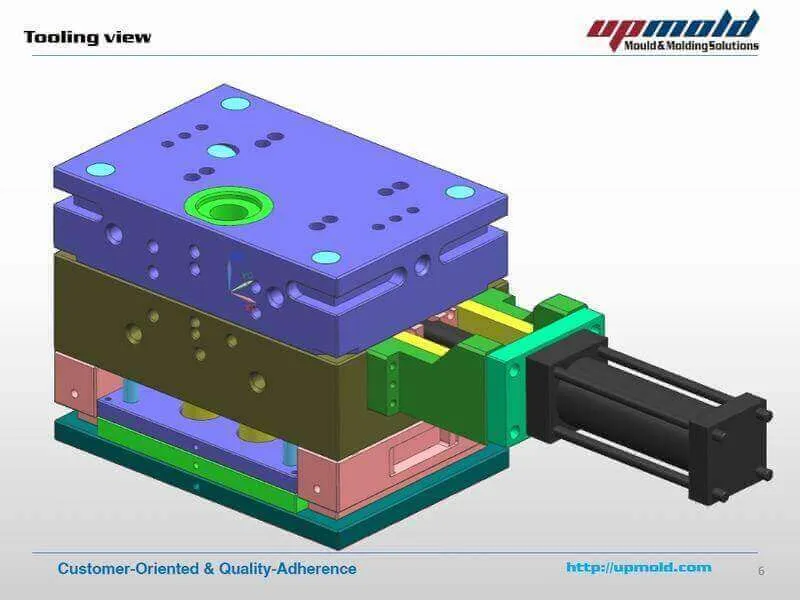

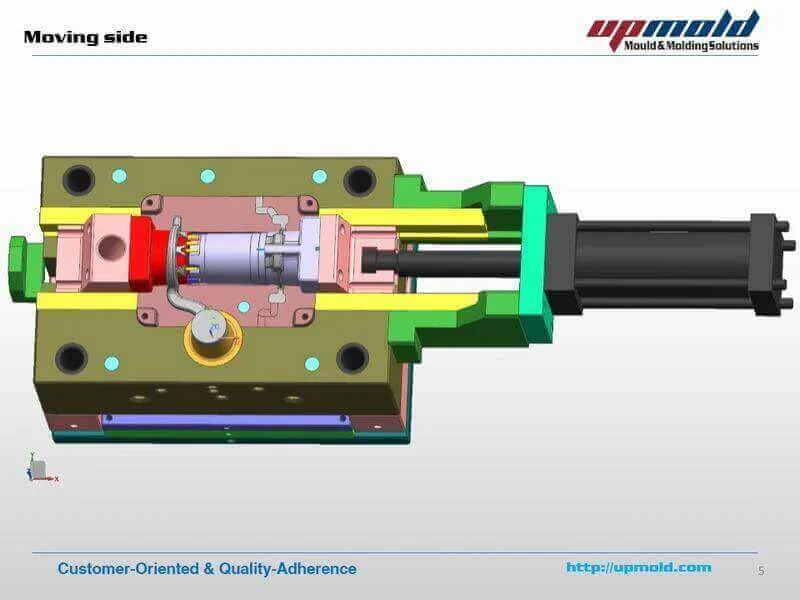

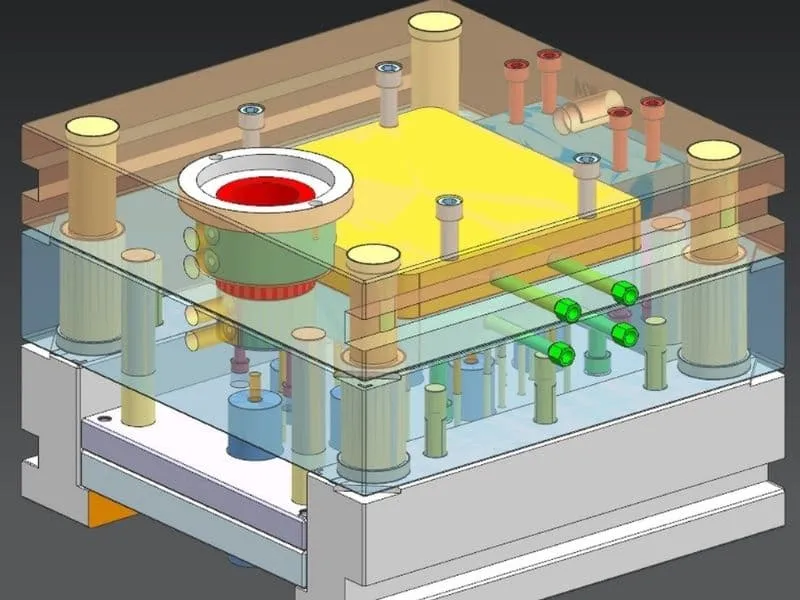

Essential Elements of Diecast Mold Design

Effective diecast mold design hinges on several essential elements, each playing a crucial role in the quality and efficiency of the casting process. Understanding and optimizing these elements is critical for minimizing defects and maximizing productivity. From material selection to cooling systems, each aspect contributes to the overall success of the mold. Proper consideration of these factors ensures the production of high-quality parts. This involves not only choosing the right materials but also fine-tuning the design to enhance metal flow, manage temperature, and facilitate easy part ejection.

Mold Material Selection

Choosing the right mold material is fundamental to ensuring durability and performance. The most common materials are tool steels, selected for their high strength, hardness, and resistance to wear and thermal fatigue. The specific type of tool steel is determined by the type of metal being cast, the casting temperature, and the required production volume. For example, high-temperature alloys are suitable for casting aluminum, while lower-temperature materials may suffice for zinc alloys. Proper heat treatment of the mold material is also essential to optimize its properties and prolong its lifespan. Selecting the right mold material is a strategic decision that impacts the longevity of the mold and the quality of the cast parts (mold-material-selection.webp).

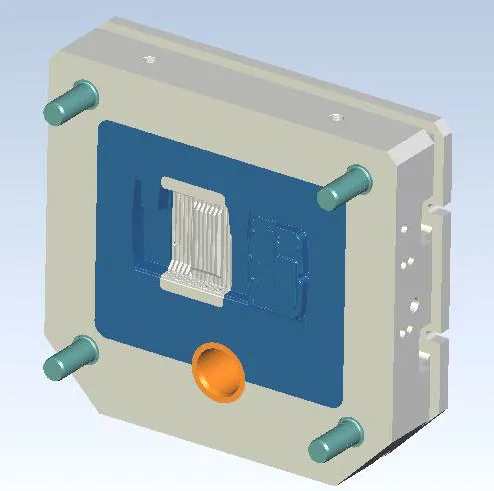

Gate Design for Optimal Flow

Gate design dictates how molten metal enters the mold cavity, influencing the filling pattern and minimizing defects. Proper gate design is crucial for directing the metal flow to prevent air entrapment, which can cause porosity and voids in the finished part. The gate’s size, shape, and location must be carefully considered based on the part’s geometry, metal type, and desired filling characteristics. Side gates, edge gates, and fan gates are some common types, each suited for different applications. The gate’s location should ensure that the metal flows uniformly, minimizing turbulence and promoting efficient solidification. Simulation software often helps in optimizing the gate design for optimal metal flow and defect prevention (gate-design-optimization.webp).

Runner System Optimization

The runner system channels the molten metal from the gate to the sprue, and its design is critical for minimizing pressure drops and ensuring uniform filling. The runners should be sized appropriately to maintain a consistent flow rate and minimize heat loss during the metal’s transit. Smooth, streamlined runner designs reduce turbulence and air entrapment. Balancing the runner system is crucial, especially for molds with multiple cavities, to ensure that each cavity fills at the same rate. Using simulation tools can also help in optimizing runner designs, providing insights into the metal’s flow behavior and identifying potential issues before manufacturing. Properly designed runners optimize the flow of metal, ensuring that the mold fills uniformly.

Venting Strategies to Prevent Defects

Effective venting is crucial for allowing air and gases to escape as the molten metal fills the mold. Inadequate venting can lead to trapped air, causing porosity, blisters, and incomplete filling. Venting strategies include strategically placed vents, overflows, and vacuum systems. Vents are typically narrow channels that allow air to escape without allowing the molten metal to flow out. The positioning and size of vents depend on the part’s geometry and filling pattern. Overflows provide a reservoir for excess metal and air, preventing them from affecting the part. Vacuum systems can also be used to remove air from the mold during the casting process, improving part quality and reducing defects.

Cooling System Design for Efficiency

The cooling system is fundamental to controlling the solidification rate and minimizing cycle times. Efficient cooling ensures that the part solidifies uniformly, reducing warpage and dimensional inaccuracies. Cooling channels, usually drilled within the mold, circulate coolant, typically water, to extract heat. The design of the cooling system, including the placement, size, and configuration of cooling channels, is a critical parameter. A well-designed cooling system promotes uniform cooling throughout the mold, leading to consistent part quality and improved production efficiency. Proper cooling channel placement prevents hotspots, ensuring consistent temperatures and reducing the cycle time (cooling-system-design.webp).

Advanced Techniques in Diecast Mold Design

Beyond the fundamentals, advanced techniques in diecast mold design can significantly improve the performance and capabilities of the casting process. These techniques often involve the use of specialized software and methods to optimize design and improve the overall efficiency of the process. Implementing advanced techniques requires a deeper understanding of materials, metal flow dynamics, and the principles of thermodynamics.

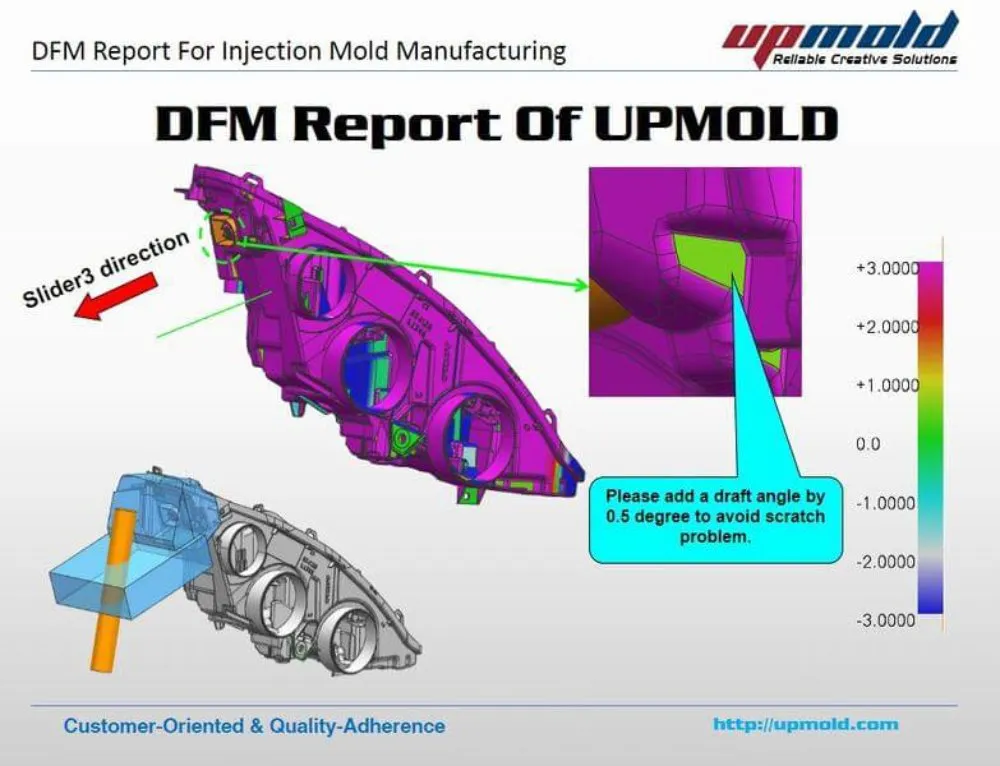

Simulation Software for Design Validation

Simulation software plays a crucial role in validating mold designs before manufacturing, enabling engineers to predict metal flow, solidification patterns, and potential defects. Software tools like Moldflow and Magma can simulate the die-casting process, allowing designers to optimize the gate, runner, and cooling system. Simulation helps identify issues such as air entrapment, shrinkage, and warpage, allowing for adjustments to the mold design. This reduces the need for physical prototyping, minimizes development costs, and accelerates the time to market. Simulation software provides invaluable insights into the mold’s performance and helps refine the design for optimal results (simulation-software-validation.webp).

Hot Runner Systems and Their Advantages

Hot runner systems, where molten metal remains liquid throughout the runner system, offer significant advantages over conventional cold runner systems. They eliminate the need for sprue and runner removal, reducing waste and cycle times. Hot runners provide better control over the metal flow, leading to improved part quality and dimensional accuracy. These systems are particularly beneficial for producing complex parts with multiple cavities. However, hot runner systems require careful temperature control and can be more complex to design and maintain. Hot runner systems are excellent for improving efficiency and reducing material waste.

Surface Treatment for Enhanced Mold Life

Surface treatments are applied to molds to improve their wear resistance, corrosion resistance, and thermal properties, thereby extending their lifespan. Treatments like nitriding, carburizing, and PVD coatings can increase the hardness and durability of the mold surface, reducing wear from the abrasive effects of molten metal. Surface treatments also enhance the mold’s resistance to thermal fatigue and corrosion, leading to higher production volumes and reduced downtime. The choice of surface treatment depends on the material being cast, the casting temperature, and the desired production volume. They ensure that the molds can withstand the harsh conditions of die casting, maintaining part quality and reducing production costs.

Common Defects and Troubleshooting in Diecast Mold Design

Despite careful design and manufacturing, diecast parts can still exhibit defects. Understanding the common issues and implementing effective troubleshooting strategies is crucial for maintaining quality and productivity. By diagnosing and addressing these issues, manufacturers can minimize waste, improve part quality, and optimize the die-casting process.

Porosity Issues and Solutions

Porosity refers to the presence of voids within the cast part. It can result from trapped air, dissolved gases in the molten metal, or shrinkage during solidification. To minimize porosity, it’s essential to optimize venting, control metal flow, and degas the molten metal. Adjusting the gate design to improve the metal flow pattern and reduce turbulence can help prevent air entrapment. Using vacuum systems to extract air from the mold can also be effective. The proper selection of casting parameters, such as injection speed and pressure, plays a crucial role in preventing porosity. Careful control over the temperature and chemistry of the molten metal is equally important (common-diecast-defects.webp).

Shrinkage and Warpage Control

Shrinkage occurs as the metal cools and solidifies, which can lead to dimensional inaccuracies and warpage. Warpage is the distortion of the part due to uneven cooling. To control these issues, uniform cooling rates throughout the mold are crucial, which can be achieved by optimizing the cooling system and ensuring consistent mold temperatures. Careful consideration of part design, especially wall thickness, can also minimize shrinkage and warpage. Using simulation tools to predict and compensate for shrinkage during the mold design phase is also highly effective. Maintaining uniform temperatures and flow patterns are essential for minimizing shrinkage and warpage.

Ejector Pin Marks and Mitigation

Ejector pins are used to push the solidified part out of the mold. The marks left by these pins can sometimes affect the part’s appearance and functionality. To minimize ejector pin marks, it is crucial to optimize pin placement, ensuring they are located in areas of the part where they are less noticeable. The use of a larger number of smaller pins can reduce the pressure on the part and the size of the marks. Proper draft angles, that is, slight tapers on the mold walls, can also aid in easy ejection and reduce the need for ejector pins. Surface finishes on the mold can also affect the visibility of ejector pin marks, with smoother surfaces leading to less pronounced marks.

Best Practices and Future Trends in Diecast Mold Design

The evolution of diecast mold design is driven by a constant quest for improved efficiency, quality, and sustainability. Incorporating best practices and staying abreast of future trends is critical for manufacturers to maintain a competitive edge. Embracing innovation and sustainability can help optimize the die-casting process.

Design for Manufacturability (DFM) Principles

Design for Manufacturability (DFM) is a design approach that focuses on optimizing a product’s design for ease of manufacturing. Implementing DFM principles in diecast mold design involves considering factors such as part geometry, wall thickness, draft angles, and tolerances during the design phase. This helps to minimize production costs, reduce defects, and improve overall efficiency. By designing parts that are easier to mold and eject, manufacturers can reduce cycle times and minimize the risk of defects. Adhering to DFM principles optimizes the design for the manufacturing process and increases efficiency (design-for-manufacturability.webp).

Sustainability in Diecast Mold Design

Sustainability is becoming increasingly important in manufacturing, and diecast mold design is no exception. Using sustainable materials, optimizing processes for energy efficiency, and reducing waste are all critical aspects of sustainable diecast mold design. This can include the use of recycled materials, minimizing material usage through design, and implementing energy-efficient cooling systems. Sustainable practices also include the use of efficient mold coatings to extend mold life and reduce waste. Adopting eco-friendly practices helps reduce environmental impact and contributes to a more sustainable manufacturing future.