What is Diecast Cars Material

Diecast cars are miniature replicas of real vehicles, prized by collectors and enthusiasts for their detail and craftsmanship. The term “diecast” refers to the manufacturing process, which involves injecting molten metal into a mold (die) under high pressure. But what exactly are these miniature marvels made of? Understanding the materials used in diecast cars is crucial for collectors, as it impacts their durability, appearance, and value. The primary materials used, manufacturing processes, and factors to consider when choosing a diecast car are all important aspects for both novice and experienced collectors. This article will delve into the core components, offering a comprehensive guide to the materials that bring these miniature vehicles to life.

The Primary Materials

The primary material in diecast cars is typically a zinc alloy. This is because of its ability to accurately capture fine details and its durability, while also being cost-effective for mass production. However, a variety of other materials are employed. The materials used significantly influence the final product’s characteristics. They affect everything from the model’s weight and feel to its visual appeal and longevity.

Zinc Alloy

Zinc alloy, often combined with small amounts of other metals like aluminum, magnesium, and copper, forms the main body and chassis of most diecast cars. The popularity of zinc alloy in this industry stems from its low melting point, good fluidity, and ability to reproduce fine details. This material is also strong and relatively resistant to wear, which is essential for models that are frequently handled or displayed. This ensures that intricate designs, such as grilles, door handles, and other small features, are accurately represented. Many consider zinc alloy the gold standard in diecast car materials due to its excellent balance of cost, durability, and detail capability.

Steel

Steel is sometimes used for certain components, such as axles or chassis parts, where greater strength or load-bearing capability is required. While steel may not be as easily cast as zinc alloy, its superior strength makes it suitable for components that need to withstand stress. Steel is often treated to prevent rust and corrosion, ensuring that these parts remain in good condition. In some cases, particularly in older or more specialized models, steel might be used more extensively, contributing to the car’s overall weight and feel.

Aluminum

Aluminum can be found in the more premium diecast car models. Its lightweight nature makes it ideal for components where weight reduction is desired, such as engine blocks or certain body parts. While aluminum can be slightly more expensive, it offers excellent corrosion resistance and can be easily machined to produce intricate designs. Collectors sometimes prefer aluminum components for their high-quality finish and the overall premium feel they provide. The inclusion of aluminum often indicates a model aimed at a higher level of detail and realism.

Plastic Components

In addition to metals, plastic plays a significant role in diecast car construction. It is used for various parts, including the interior, tires, windows, and sometimes even the body components. The use of plastic allows for the creation of highly detailed elements that may be difficult or expensive to produce using metal. The specific type of plastic used greatly affects the model’s appearance and durability. These plastic components help achieve realistic details and enhance the car’s overall aesthetic appeal. Plastic is often chosen for its versatility and cost-effectiveness in mass production.

Types of Plastic Used

Several types of plastic are used in diecast cars. ABS (Acrylonitrile Butadiene Styrene) is a common choice for interior parts and smaller components because it is durable and easily molded. PVC (Polyvinyl Chloride) may be used for tires due to its flexibility and ability to mimic the appearance of rubber. Clear plastics like acrylic are used for windows, offering excellent transparency and scratch resistance. The selection of each plastic type depends on its suitability for the part and the desired characteristics of the final product. Each plastic is specifically chosen to meet specific design and functional requirements.

Importance of Materials

The materials used in a diecast car are crucial, affecting its longevity, realism, and value. High-quality materials ensure that the model is durable, resistant to damage, and capable of retaining its appearance over time. The choice of materials impacts the level of detail that can be achieved, with premium materials often allowing for finer features and a more realistic finish. Collectors often prioritize models made with high-quality materials. The selection of materials directly influences the overall experience and the enjoyment derived from the model car.

Durability and Lifespan

The materials used in diecast cars greatly influence their durability and lifespan. Metal components, especially zinc alloy and steel, are robust and can withstand considerable wear and tear. Properly manufactured and maintained diecast cars can last for many years, often becoming valuable collectibles. The quality of the metal and the manufacturing process affects the car’s resistance to damage, such as chipping, scratching, or corrosion. Plastic components, while generally durable, may be more susceptible to degradation over time, particularly if exposed to direct sunlight or extreme temperatures. The lifespan of a diecast car is a significant factor in its appeal and value to collectors.

Impact on Value and Collectibility

The materials used significantly impact the value and collectibility of diecast cars. Models made with premium materials, such as aluminum, are often considered more valuable due to their superior quality and detail. Limited-edition models, or those with unique material combinations, also tend to command higher prices. The use of high-quality materials enhances the overall aesthetic appeal of the model and contributes to its long-term value. Collectors often seek out models with exceptional detailing, which is usually achieved through the use of top-tier materials. The materials directly influence the model’s scarcity, which is a major factor in the collectibility of the model.

Manufacturing Process and Materials

The manufacturing process of a diecast car heavily relies on the properties of the materials used. The process begins with the creation of molds, which are typically made from steel, capable of withstanding the high pressures and temperatures of the die-casting process. The molten metal is injected into these molds, and the materials are then shaped. The choice of materials, particularly the metal alloy, affects how accurately the fine details of the car can be reproduced. The finishing touches, such as painting and the addition of plastic components, further enhance the final product. Understanding the manufacturing process helps collectors appreciate the work that goes into creating these miniature vehicles.

Die-casting Process Explained

The die-casting process is central to the production of most diecast cars. The process involves forcing molten metal, typically a zinc alloy, under high pressure into a mold. This mold is a precision-engineered tool that defines the shape of the car. Once the metal solidifies, the mold is opened, and the finished part is extracted. This process allows for high-volume production with excellent dimensional accuracy, which is crucial for capturing the intricate details of real-world vehicles. The efficiency of the die-casting process makes it possible to create detailed models at a scale that makes them affordable.

Surface Finishing and Coatings

After the die-casting process, the diecast car undergoes several surface finishing steps. These steps include cleaning, smoothing, and preparing the surface for painting. High-quality paints and coatings are applied to give the car its realistic appearance and protect the metal from corrosion. Clear coats may also be applied to enhance the shine and protect the paint. The finishing process contributes significantly to the overall aesthetic of the model. The application of surface coatings improves the longevity and the visual appeal of the finished product, and contributes to the long-term value of the car.

Factors to Consider When Choosing

When choosing a diecast car, collectors should consider several factors related to materials. These factors affect the overall quality, authenticity, and value of the model. These considerations include the scale and level of detail, the authenticity of the model, and the overall cost and budget for the collection. By paying attention to these aspects, collectors can make informed decisions and expand their collections with valuable pieces.

Scale and Detail

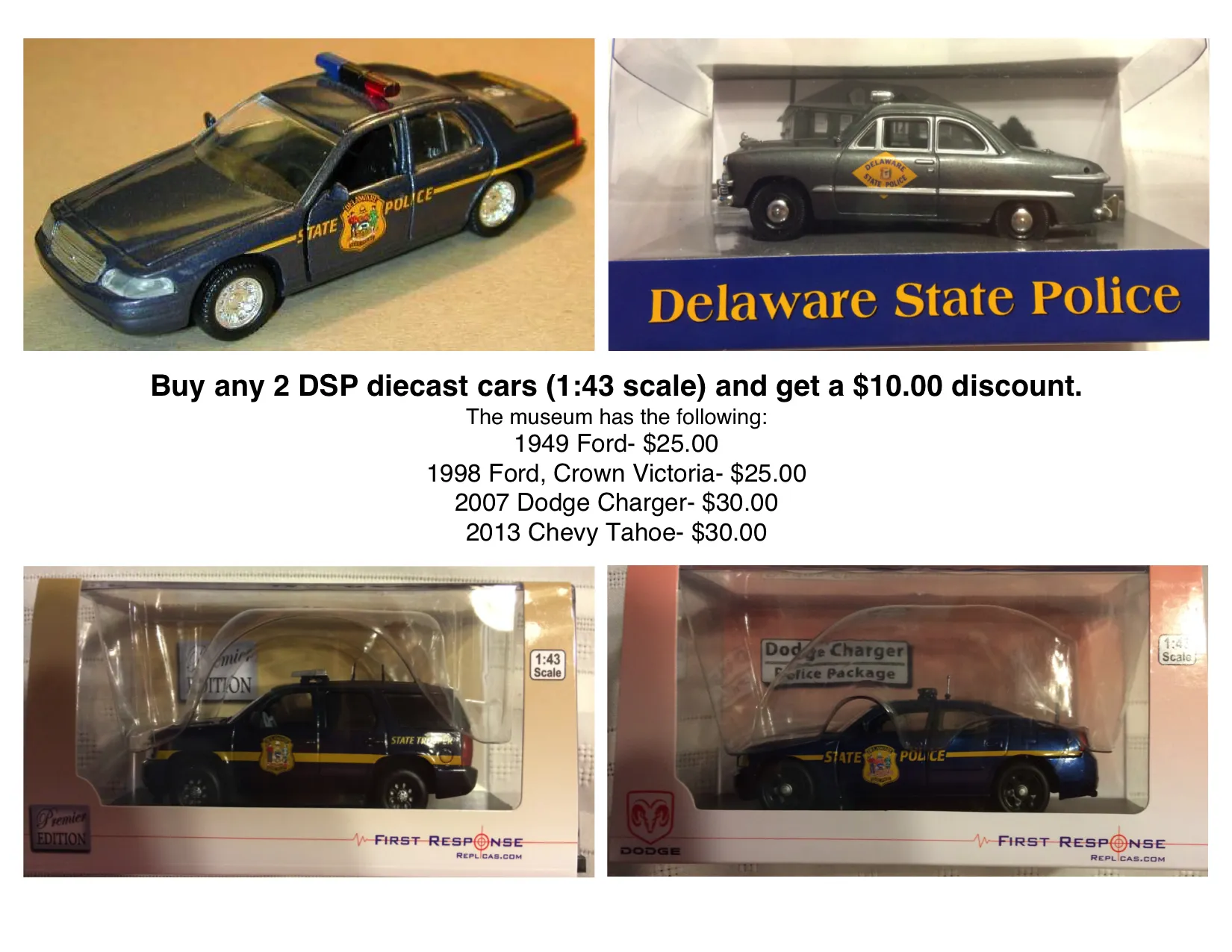

The scale and level of detail are essential considerations when choosing a diecast car. Different scales (e.g., 1:18, 1:24, 1:43) offer varying levels of detail. Larger scales typically allow for more intricate features, but they also take up more space and can be more expensive. The materials used directly affect the level of detail that can be achieved. High-quality metals and precise manufacturing techniques are required to replicate the fine features. Collectors often look for models with detailed interiors, engine compartments, and accurate paint finishes. Pay attention to the scale and level of detail to ensure the model meets your collecting criteria.

Authenticity of the Model

The authenticity of a diecast car refers to how closely it resembles the real-life vehicle. This includes the accuracy of the body shape, the detailing, and the paint finish. The materials used contribute to the model’s authenticity, as high-quality materials allow for more accurate replication of the original car. Collectors value models that are true to their real-world counterparts. The quality of the materials influences how well the model captures the essence of the original vehicle. Look for models that have been officially licensed by the car manufacturer. This licensing ensures a higher degree of accuracy and authenticity.

Cost and Budget

The cost and budget should always be considered when selecting diecast cars. The price can vary greatly, depending on the materials used, the scale, the level of detail, and the brand. Limited-edition models and those made with premium materials will typically cost more. Setting a budget can help you narrow your choices and focus on models that fit your collecting goals. It’s important to balance your desire for quality with your financial constraints. Remember, the value of a diecast car is not solely determined by its price, but also by its rarity, condition, and historical significance. Consider a variety of factors before making a purchase.

Care and Maintenance of Diecast Cars

Proper care and maintenance are essential for preserving the condition and value of your diecast car collection. Protecting your models from damage and ensuring they are stored correctly will help them last longer and maintain their appeal. Regular cleaning and careful handling are key to preserving the aesthetic and monetary value of your collection. By adopting these practices, collectors can extend the life of their models and keep them in prime condition for years.

Cleaning and Storage

Regular cleaning and proper storage are crucial for keeping your diecast cars in good condition. Use a soft, microfiber cloth to dust the models regularly. Avoid using harsh chemicals or abrasive cleaners. Store your models in a dry, temperature-controlled environment to prevent damage from moisture and extreme heat. Consider using display cases or shelves to protect them from dust and accidental damage. Proper cleaning and storage will prevent scratches and corrosion. This preserves the condition of your models and protects their value for a long time.

Protecting from Damage

Protecting your diecast cars from damage involves several practices. Handle your models with care, and avoid dropping or bumping them against hard surfaces. Keep them away from direct sunlight, which can fade the paint and damage the plastic components. Use protective packaging, such as the original boxes or display cases. Regular inspections can help identify any potential issues early on. Following these tips will preserve the value and appearance of your collection. By taking proactive measures, you can extend the life of your diecast cars and prevent costly repairs or replacements.