The Appeal of Custom Diecast Boxes

Custom diecast boxes are more than just containers they are integral to the collecting experience. These boxes serve as the first point of contact, significantly impacting a collector’s initial impression. A well-designed box enhances the perceived value of the diecast model, adding to its desirability and collectibility. From a marketing perspective, they act as powerful branding tools, showcasing a brand’s commitment to quality and attention to detail. This is especially crucial in the competitive world of collectibles, where presentation can be as important as the product itself. The allure lies in how they transform a simple product into a premium, collectible item.

Why Custom Diecast Box Designs Matter

The design of a custom diecast box can significantly affect the perception and value of the model it houses. An attractive and functional box protects the diecast and adds to its aesthetic appeal, thus increasing its value. Collectors often keep the original packaging, seeing it as an essential part of the item’s history and authenticity. Moreover, a well-designed box tells a story about the product. It communicates the brand’s values, its commitment to quality, and its understanding of what collectors seek. In a market where details make the difference, thoughtful design can set a model apart and boost its demand.

Enhancing Collectibility

The quality of a custom diecast box greatly influences how collectors view a model’s potential for value appreciation. Rare or limited-edition boxes often increase a model’s worth, as they become sought-after items in their own right. The design elements, such as the materials used, the artwork, and any special features, contribute to the box’s exclusivity. The overall presentation enhances the collecting experience, making each model feel more special. This is why the design of a custom diecast box isn’t just a practical consideration; it’s a crucial element in cultivating a strong collector’s market.

Secret 1 Material Mastery

The choice of materials for a custom diecast box is the foundation of its quality and appeal. The right materials protect the model from damage during shipping and storage and communicate the brand’s quality. The durability and aesthetic properties of the chosen material significantly impact the collector’s perception of value. Consideration must be given to the material’s printability, its resistance to wear and tear, and its environmental impact. Moreover, material choices can dramatically affect the overall look and feel, ranging from a premium, luxurious experience to a more rugged, industrial aesthetic. Thus, the selection of materials is critical to the success of custom diecast box designs.

Choosing the Right Materials

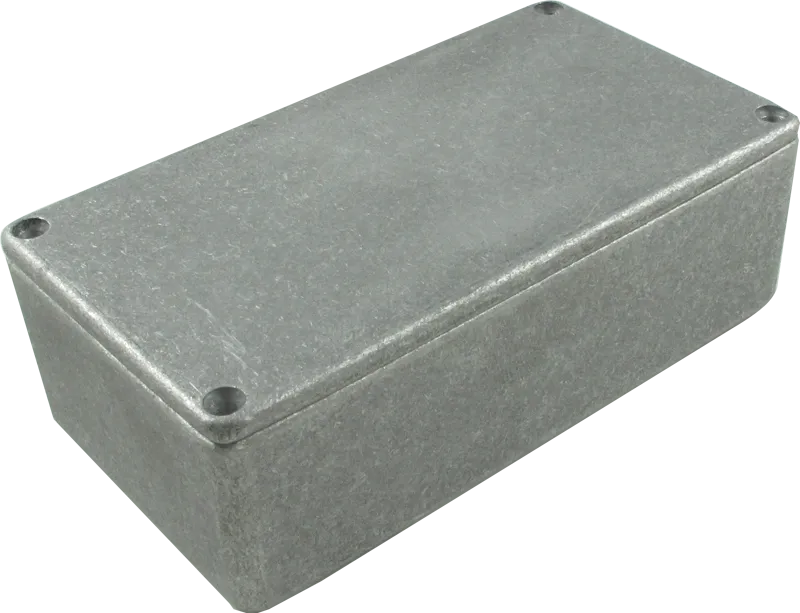

Several materials offer unique benefits for custom diecast boxes, each affecting the box’s appearance, durability, and cost. High-quality cardboard is a versatile and cost-effective choice, providing excellent printability and customization options. Plastic offers durability and the potential for clear window displays, making the diecast visible without opening the box. Metal boxes can convey a premium feel and offer superior protection, although they typically come with higher production costs. The best choice depends on the target market, the brand image, and the desired level of protection and presentation. Weighing these factors allows for an informed decision that aligns with the brand’s objectives.

Cardboard, Plastic, or Metal

Each material presents a unique set of advantages and disadvantages for custom diecast box designs. Cardboard provides a balance of cost-effectiveness, printability, and recyclability, making it a popular choice. Plastic offers superior protection and allows for attractive window displays, enabling collectors to view the model without opening the box. Metal, while the most expensive option, offers unmatched durability and creates a premium, high-end feel. The selection process should involve a consideration of the required level of protection, the brand’s budget, and the desired aesthetic. The key is to match the material to the diecast’s value and the brand’s overall strategy.

Secret 2 Design for Display

The design of a custom diecast box can greatly enhance the presentation and appeal of the model inside. Consideration should be given to how the box showcases the diecast itself. Clear windows can let collectors view the model without removing it, protecting the diecast while still making it accessible. The box’s shape and layout must also protect the model during shipping and handling. Thoughtful design elements, such as interior inserts, create a secure and visually appealing display. The ultimate goal is to create a box that not only protects the diecast but also accentuates its features and entices collectors.

Showcasing the Diecast

The key to an effective custom diecast box is presenting the model beautifully. Design elements such as strategically placed windows, high-quality photography, and attractive graphic design draw attention to the diecast. The box’s interior should be designed to hold the model securely, protecting it from damage and highlighting its features. The use of color and design elements should complement the model itself. The design should reflect the product’s value. A well-designed box will protect the diecast and increase its appeal to collectors.

Window Placement and Aesthetics

Window placement is critical to a custom diecast box’s effectiveness. The position and size of the window must allow viewers to fully appreciate the model without compromising its security. The use of clear, high-quality materials like transparent plastic enhances the viewing experience. The design of the window itself can enhance aesthetics, using shapes and angles to create visual interest. The window should complement the graphic design of the box, enhancing the overall presentation. Thoughtful window placement creates a sense of anticipation and allure. It provides a peek at the model without giving it all away, thus increasing the appeal to potential buyers.

Secret 3 Branding Brilliance

Branding plays a crucial role in the design of a custom diecast box. The box serves as a critical touchpoint for brand communication. Using logos, colors, and design elements that accurately represent the brand’s identity ensures recognition. This builds trust and creates a consistent brand experience. High-quality printing and finishing techniques contribute to the perception of value and reinforce the brand’s commitment to excellence. Brand consistency across all packaging elements creates a memorable and appealing experience for collectors, solidifying brand loyalty and increasing the perceived value of the diecast models.

Logo Placement and Color Schemes

The strategic placement of the logo and the selection of the color scheme are vital components of a custom diecast box design. The logo should be prominently displayed but not overwhelming, ensuring brand recognition without detracting from the model itself. The color scheme should align with the brand’s identity and appeal to the target audience. Colors can evoke emotions. The right color combinations can enhance the overall aesthetic appeal of the packaging. Proper color use makes the brand memorable. These elements, when combined, create a cohesive and compelling brand experience.

Creating a Brand Identity

Establishing a strong brand identity through the design of the custom diecast box is essential. All the design elements must work together to communicate the brand’s story, values, and unique selling points. The box’s visual elements should tell a story, creating a connection with collectors. It is very important to showcase the quality, attention to detail, and brand’s commitment to excellence. A cohesive and recognizable brand identity helps to distinguish the diecast model in a competitive market, building brand loyalty. Custom diecast boxes become powerful tools to engage with customers and shape the perception of the product.

Secret 4 Structural Integrity

The structural integrity of a custom diecast box is non-negotiable. It must provide protection during shipping, handling, and storage. The box should withstand environmental factors and external pressures. High-quality construction methods and materials guarantee the model’s safety. Proper structural design preserves the model’s value. Collectors appreciate the box’s integrity. A well-built box enhances the collectible’s appeal and contributes to its long-term value.

Protecting the Diecast

The primary function of a custom diecast box is to safeguard the model. The box’s construction should provide protection against impacts, moisture, and other environmental factors. Internal features such as inserts and foam padding add extra protection. The choice of materials and the overall design should prioritize the safety of the model, ensuring that it arrives in perfect condition. A well-protected diecast not only maintains its value but also enhances the collector’s enjoyment. Designing for protection is essential for creating a positive experience for the end-user.

Box Construction Techniques

Advanced construction techniques are essential for building robust and reliable custom diecast boxes. Techniques like precise die-cutting, folding, and gluing ensure accurate dimensions. The use of reinforced corners and edges improves the box’s durability, while specialized closures keep the box secure. Selecting the appropriate techniques will depend on the material, the model’s size and weight, and the intended use. Investing in high-quality construction methods shows a commitment to quality and is important for creating durable and aesthetically pleasing packaging.

Secret 5 Printing Perfection

The printing quality of a custom diecast box profoundly impacts its visual appeal and value. The printing process must be precise, using high-resolution images, vibrant colors, and sharp text to ensure a premium look. Advanced printing techniques, such as offset or digital printing, allow for complex designs and high-quality finishes. This attention to detail underscores the brand’s commitment to quality and differentiates the product. High-quality printing enhances the collector’s experience. The goal is to create packaging that attracts collectors and enhances the value of the diecast model.

High-Quality Printing Techniques

Several printing techniques are used to produce high-quality custom diecast boxes, each offering unique advantages. Offset printing is well-suited for large print runs, delivering exceptional color accuracy and detail. Digital printing is ideal for short runs. It enables customization and variable data printing. The selection depends on project-specific needs. The choice of technique will affect the cost, quality, and turnaround time. It’s essential to use printing processes that meet the brand’s aesthetic requirements. These printing techniques help to bring the design to life and improve the overall packaging.

Gloss, Matte, or Spot UV

Finishing touches, like gloss, matte, or spot UV coatings, can drastically affect the final look and feel of the custom diecast box. Gloss finishes add shine and create a vibrant appearance. Matte finishes provide an elegant, understated look. Spot UV coatings add a tactile element and highlight specific design features, creating visual interest. The correct choice should complement the overall design and branding, enhancing the perceived value of the product. These finishes enhance the packaging’s presentation and provide a memorable experience. Proper finishing makes a significant difference in creating a superior custom diecast box.