What is Diecast and Chroming?

Diecast models, beloved by collectors and hobbyists alike, are miniature replicas of vehicles crafted using a specific manufacturing process. This involves injecting molten metal, typically zinc alloys, into molds to create intricate and detailed models. The term “chroming,” in this context, refers to the process of applying a thin layer of chromium to the surface of the diecast model to give it a shiny, reflective finish. This is often done to simulate the chrome trim found on real vehicles, enhancing the model’s realism and aesthetic appeal. The appeal of chrome on diecast models extends beyond mere aesthetics. It adds a layer of durability and protection against corrosion. Furthermore, chrome’s reflective properties accentuate the model’s details, making them visually more striking and appealing to collectors. This combination of beauty, protection, and detail is a key reason why chrome finishes are so sought after in the diecast world. The process itself is a testament to both artistry and scientific precision, transforming a basic diecast shell into a miniature masterpiece.

Diecast Material and Compatibility

The success of chroming a diecast model significantly depends on the material it’s made from. Diecast models are usually made from zinc alloys, which are generally compatible with the chroming process. However, the presence of other materials or coatings can affect the outcome. It’s essential to ensure the model’s surface is clean and free from any existing paints, primers, or sealants, as these can interfere with the chrome’s adhesion. The zinc alloy composition also influences the chroming result. The alloy’s purity and the absence of contaminants are crucial for achieving a smooth, even chrome finish. Surface imperfections, such as scratches or pits, must be addressed before chroming, as they will be amplified by the reflective nature of the chrome. Proper material preparation is therefore vital for achieving a high-quality chrome finish, ensuring that the final product is both visually appealing and durable. Different alloys will react differently, and some may require specialized preparation techniques to optimize the chroming process.

The Chroming Process Step-by-Step

Chroming a diecast model is a detailed process that involves several critical steps. First, the model must be meticulously cleaned to remove any dirt, grease, or existing coatings. This is often achieved through a combination of degreasing solutions and careful polishing. Then, the surface needs to be prepared, which may involve smoothing out imperfections and ensuring a uniform surface texture. The next step is the application of a base coat, typically a layer of copper or nickel, to provide a suitable surface for the chrome to adhere to. The chrome layer is then applied through an electroplating process, where the model is immersed in a chroming solution, and an electric current is used to deposit a thin layer of chromium onto the surface. This layer gives the model its characteristic shine and protective properties. The model then goes through a final polishing stage to enhance the chrome’s luster and remove any imperfections. Each stage is critical and influences the final appearance and durability of the chrome finish. The precision and quality of each step directly impact the overall look and longevity of the chrome on the diecast model.

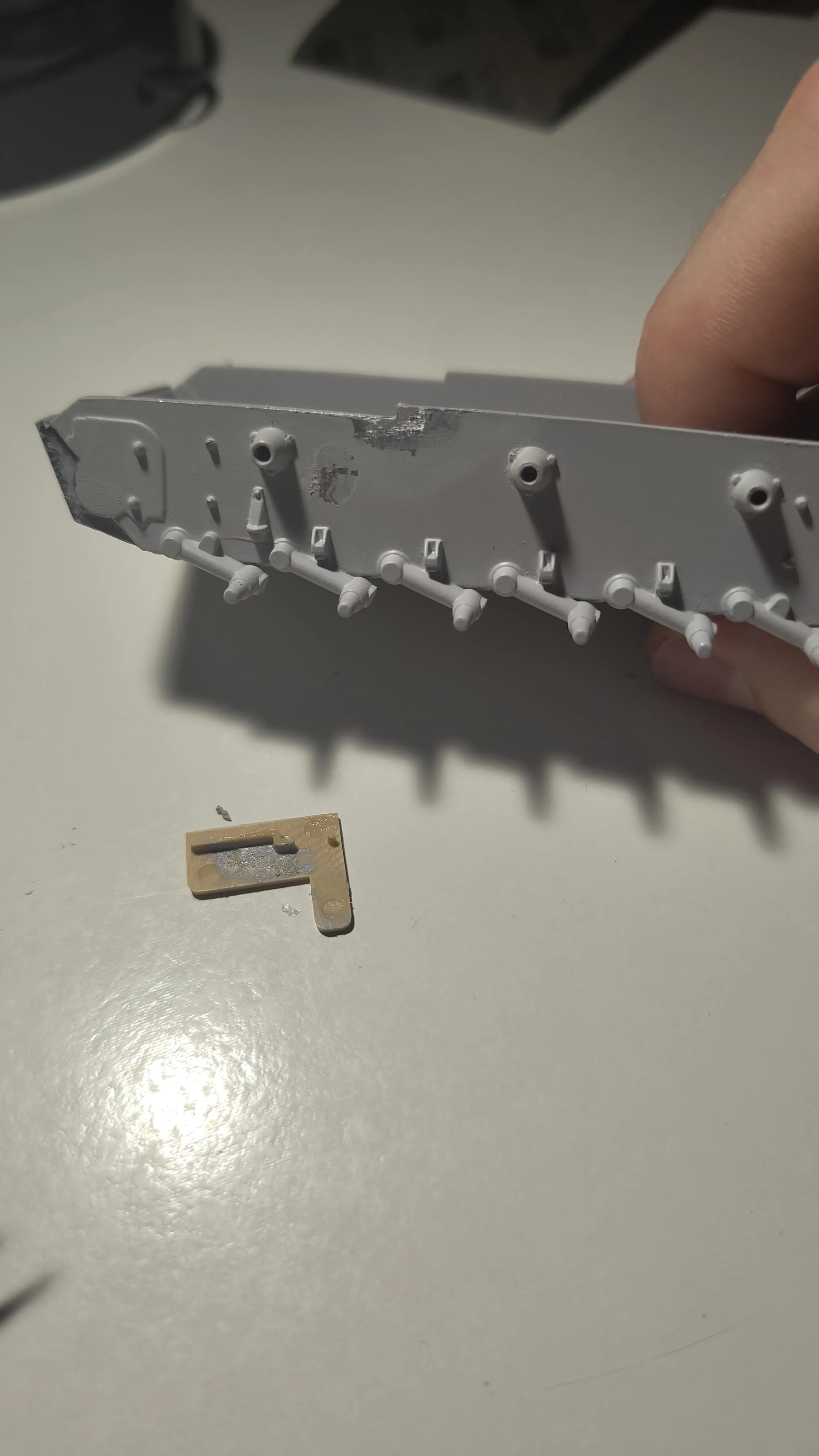

Surface Preparation for Chrome

Surface preparation is the most crucial step in chroming a diecast model, determining the final quality of the chrome finish. This involves several meticulous processes. First, cleaning is performed to eliminate any contaminants such as dust, oils, or old paint. This can involve using specialized solvents or ultrasonic cleaners. The surface is then polished to remove imperfections like scratches, pits, or mold lines. Polishing typically involves using a series of abrasive compounds, gradually increasing the fineness to achieve a smooth surface. The model is then thoroughly rinsed to ensure no residue remains. The goal of this preparatory phase is to create a perfect surface that will allow the chrome to adhere evenly and reflect light uniformly. Neglecting this step will result in a poor chrome finish, highlighting imperfections rather than concealing them. Careful attention to detail during surface preparation ensures the chrome finish is flawless and long-lasting.

Applying the Chrome Coating

Applying the chrome coating itself is a complex process, usually done via electroplating. The diecast model, prepared with a base coat of copper or nickel, is immersed in a chroming solution. An electrical current is then passed through the solution, causing chromium ions to deposit onto the model’s surface. The thickness of the chrome layer is carefully controlled to achieve the desired appearance and durability. This process requires precise control of current, voltage, and time to ensure uniform coverage. The quality of the chroming solution is also critical. The solution’s composition and purity directly influence the chrome’s shine and adhesion. After the chrome coating is applied, the model is thoroughly rinsed to remove any remaining chemicals. The application of a clear coat can further protect the chrome from scratches and environmental damage, enhancing its longevity. Proper electroplating techniques and the use of high-quality materials are crucial to achieve a durable, beautiful chrome finish on the diecast model.

Post-Chroming Treatments and Finishing

After the chroming process is complete, several treatments and finishing steps are performed to enhance the chrome’s appearance and protect it. The model may undergo a final polishing step to remove any remaining imperfections or to further enhance its shine. This polishing is done using fine polishing compounds and soft cloths. A clear coat is often applied to protect the chrome from scratches, fading, and environmental damage. This clear coat acts as a barrier, preserving the chrome’s luster. Additionally, some models may receive detailed paintwork, such as adding black accents in the crevices or painting specific features. These details add depth and realism to the model. Careful inspection is conducted at this stage to ensure the model meets quality standards, with any imperfections addressed. Proper post-chroming treatments and finishing steps are essential for a professional-quality result that is both visually stunning and long-lasting. The goal is to create a model that not only looks great but also withstands the test of time.

Factors Affecting Chrome Quality on Diecast

Several factors influence the quality of chrome finishes on diecast models, including the surface preparation, the materials used, and the chroming process itself. A key factor is the cleanliness and smoothness of the model’s surface before chroming. Any imperfections, such as scratches or contaminants, will be visible after chroming. The quality of the base coat, typically copper or nickel, is also important, as it provides the foundation for the chrome layer. The composition and purity of the chroming solution significantly affect the chrome’s shine and durability. Environmental conditions during the chroming process, like temperature and humidity, can also influence the outcome. Skilled technicians who have mastered the chroming process are also extremely important. These technicians can control all the variables. Proper curing and post-treatment processes further enhance the chrome’s longevity and appearance. Maintaining a strict adherence to quality control measures throughout the chroming process is crucial to achieve a high-quality, durable chrome finish on the diecast model. The interplay of these factors determines the final product’s visual appeal and its ability to withstand the test of time.

Environmental Conditions

Environmental conditions play a critical role in the quality and durability of chrome finishes on diecast models. Temperature and humidity levels during the chroming process and during the curing and finishing stages can impact the chrome’s adhesion, appearance, and resistance to corrosion. Excessive humidity can cause defects, such as blisters or uneven finishes, while extreme temperatures can affect the chemical reactions in the chroming solutions. Dust and other airborne particles can also contaminate the surface during the application and drying phases, leading to imperfections. Therefore, it’s essential to maintain a controlled environment with specific temperature and humidity levels. Cleanliness is crucial. Air filtration systems may be used to minimize airborne particles. The workspace must be kept clean. Controlling these environmental factors is necessary for achieving a high-quality, long-lasting chrome finish. It protects the integrity of the chrome and prevents issues that can affect the final appearance and durability of the model.

Types of Chrome Finishes

Diecast models can feature different types of chrome finishes, each offering a unique aesthetic appeal and durability. Bright chrome, the most common type, provides a highly reflective surface that closely resembles real chrome. This finish is achieved through a meticulous electroplating process, delivering a mirror-like shine. Matte chrome offers a subdued, non-reflective appearance, providing a more understated aesthetic. It is produced by modifying the electroplating process or applying a matte clear coat. Brushed chrome gives the appearance of brushed metal. This is achieved by creating micro-grooves on the surface of the model. Black chrome offers a dark, sleek appearance. It’s created by adding dark dyes or pigments to the chrome. The choice of chrome finish can significantly alter the model’s overall appearance, allowing for customization and stylistic variations. The right chrome finish can be selected depending on the design, desired visual effect, and the specific model’s aesthetic needs. The wide range of chrome finishes available provides modelers with the opportunity to create unique and personalized diecast masterpieces.

Maintaining Your Chrome Diecast

Proper maintenance is essential to preserve the beauty and longevity of chrome finishes on diecast models. Regular cleaning is crucial to remove dust, fingerprints, and other contaminants that can dull the chrome’s shine or cause corrosion. Cleaning should be done with a soft, clean microfiber cloth. Gentle cleaning products, specifically designed for chrome or delicate surfaces, should be used. Avoid abrasive cleaners or harsh chemicals. Store the models in a clean, dry environment away from direct sunlight and extreme temperatures. Direct sunlight can cause fading or damage to the chrome. Consider using display cases to protect models from dust and physical damage. Handle models carefully, avoiding contact with bare hands to prevent fingerprints and oils from transferring to the chrome surface. Inspect the models regularly for signs of damage or corrosion. By following these maintenance tips, you can ensure your chrome diecast models retain their brilliance and remain cherished collectibles for years to come. Consistent care and attention are key to preserving their value and appearance.

- Carefully cleaning the models with a soft cloth.

- Using specifically designed cleaners.

- Storing the models away from sunlight.